EASY ARC WELDING SOLUTION

The Modular Solution for shop floors

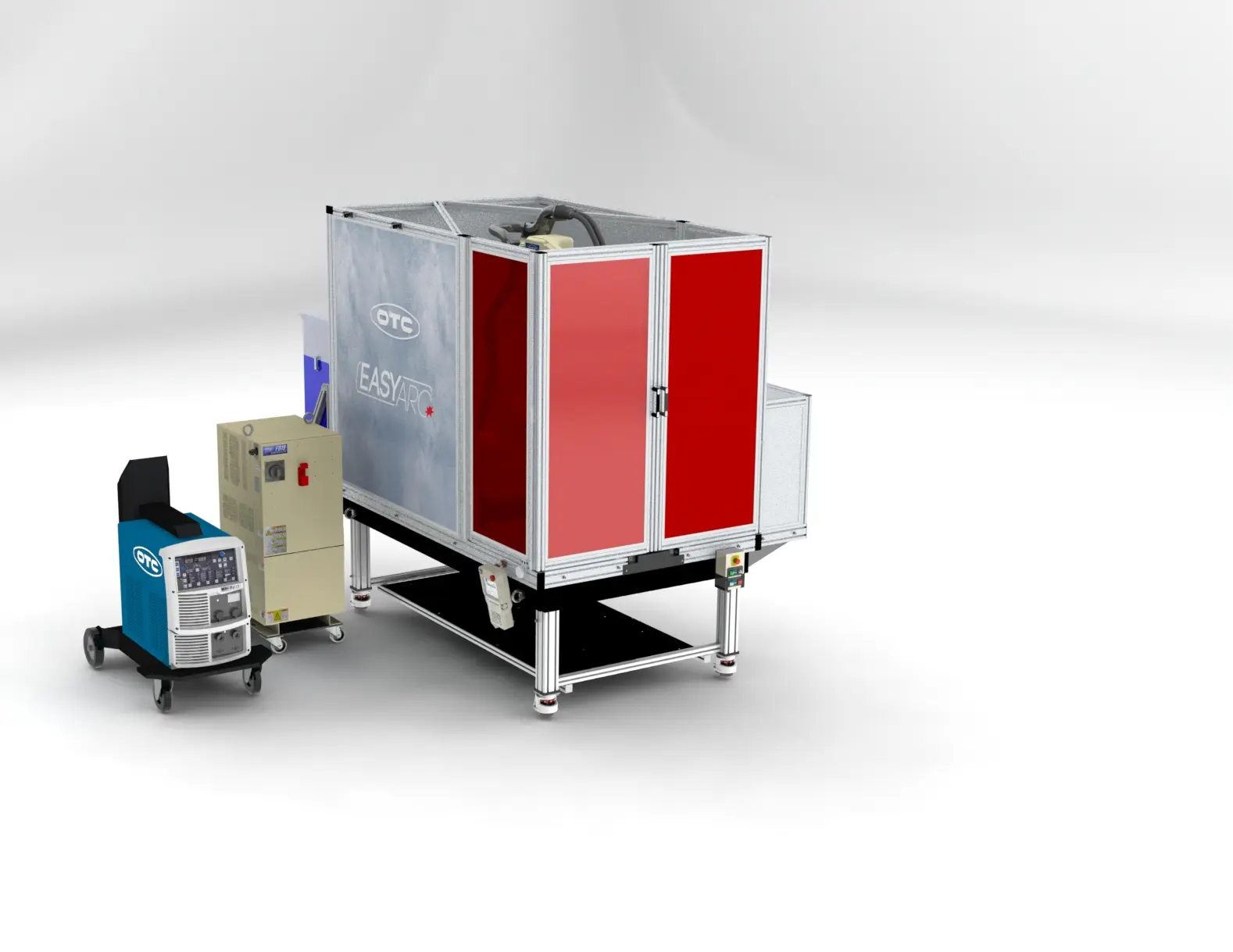

EASY ARC

EASY ARC is perfect for the medium-sized company solving the shortage of skilled workers to recruit. Automate your small batch production to keep up with demand, or repetitive tasks your skilled welders otherwise waste time having to handle. Easy Arc proves an innovate answer to today's challenges - from workshop operations to industrial companies.

Space-Saving

The EASY ARC only has a footprint of 2,2m x 1,2m.

Fits perfectly almost everywhere.

MIG/MAG or TIG

Do you need MIG/MAG or TIG welding?

We got you covered.

Customizable Options

Sometimes the standard solution is not quite right.

Let's customize your solution to your needs.

12 Months Guarentee

It's important to feel at easy when buying new automation equipment. 12 months guarantee on your EASY ARC.

3D Welding Table

With EASY ARC you can weld in any direction, anywhere on any object surface.

Can also be leased

Sometimes you only need a solution temporarily. Let's keep you going while you find a permanent solution. Decided to keep it? We will deduct the leasing fees from the purchasing price.

Who can use EASY ARC?

The EASY ARC robot cell is the solution for small batch production which requires flexible configuration. Instead of manually welding parts over and over, quickly teach the robot how it's done. The cell is simple, is easy to move around, and has a small footprint of 2,2m x 1,2m.

If you have various welding needs through the week, simply drag EASY ARC to the destination and choose the desired saved welding pattern.

Choose your EASY ARC setup

EASY ARC has two basic version. One with MIG/MAG and one with TIG. You can choose a variety of optional equipment to create the perfect application for your welding.

Popular options: welding equipment, fume extraction, positioner, sensoric, the JoyPen and Offline Programming.

Depending on the work-load, frequent new welding patterns, and conjunction with other equipment, the options may help your application succeed flawlessly. We can help find what you need.

Who can use EASY ARC?

The EASY ARC robot cell is the solution for small batch production which requires flexible configuration. Instead of manually welding parts over and over, quickly teach the robot how it's done. The cell is simple, is easy to move around, and has a small footprint of 2,2m x 1,2m.

If you have various welding needs through the week, simply drag EASY ARC to the destination and choose the desired saved welding pattern.

Choose your EASY ARC setup

EASY ARC has two basic version. One with MIG/MAG and one with TIG. You can choose a variety of optional equipment to create the perfect application for your welding.

Popular options: welding equipment, fume extraction, positioner, sensoric, the JoyPen and Offline Programming.

Depending on the work-load, frequent new welding patterns, and conjunction with other equipment, the options may help your application succeed flawlessly. We can help find what you need.

MIG / MAG PACKAGE

- 3D welding table with intelligent system grids for clamping and positioning workpieces

- Fully assembled and CE-compliant documentation

- Welbee P400 welding machine (gas-cooled inverter pulse power source)

- OTC safety technology with monitoring unit (RMU) and housing

- Six-axis robot, FD-B6, with integrated cable routing for optimal accessibility

- OTC robot welding torch with forced shutdown

Option 1 | Option 2 |

Welbee P500L welding Machine (water-cooled inverter pulse power source) | Horizontal rotary positioner, A2-1PB250, inluding synchromotion software and integration in the Easy Teach control system |

TIG PACKAGE

- 3D welding table with intelligent system grids for clamping and positioning workpieces

- Fully assembled and CE-compliant documentation

- Welbee A350P welding machine (water-cooled inverter pulse pwer source)

- OTC safety technology with monitoring unit (RMU) and housing

- Six-axis robot, FD-V8 for maximum flexibility

- OTC robot welding torch with 3D forced shutdown

Option 1 | Option 2 |

Welbee P500L welding machine (water-cooled inverter pulse power source) | Horizontal rotary positioner, A2-1PB250, including synchromotion software and integration in the Easy Teach control system. |

Receive a quote

Let's start the conversation