Hikrobot

Machine Vision & Mobile Robots

Keep your Logistics smoothly running with Mobile Robots!

Let your warehouse shine with your own army of mobile robots to assist in keeping your logistics under control. Hikrobot provides customers with safe and reliable intelligent mobile robot products and systems, and build smart internal logistics solutions in industrial factories.

Autonomouos movement of your boxes, pallets, cartons and much more. Mobile robots create a safer working environment for your employees and more cost-effective productivity in your own intelligent warehouse.

You can learn more about the different types of mobile robots you can apply right here!

Autonomous Mobile Robots

Positioning Guidance

Obtain the position information of the measured object through machine vision technology, and guide the robot to carry out a series of operations. Based on image calibration, target detection, size search and other algorithmic technologies, the main role of robot guidance related applications is to accurately obtain the coordinate position and angle of the object (object to be grasped) and target object (object to be assembled), and convert the image coordinate into the robot coordinate that can be recognized by the robot, and guide the robot to locate and assemble.

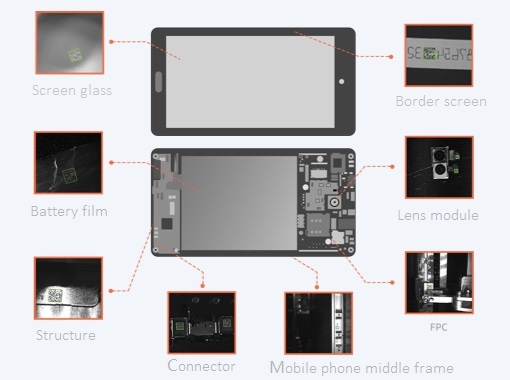

Code System Identification

The technology of electronic industry product is complex, in some links of the industry chain, the product identity ID information should be identified. Demand for electronic devices such as smartphones and tablets has surged. With the increasing number of parts and the rapid development of miniaturization of products, manufacturers are also committed to pursuing high-quality traceability management. In view of the miniaturization of electronic parts, in many cases, the traditional contact printing processing method has been changed to the non-contact high-precision laser printing and processing. Therefore, the requirements for trace printing with fineness, high quality and low damage are increasing day by day.

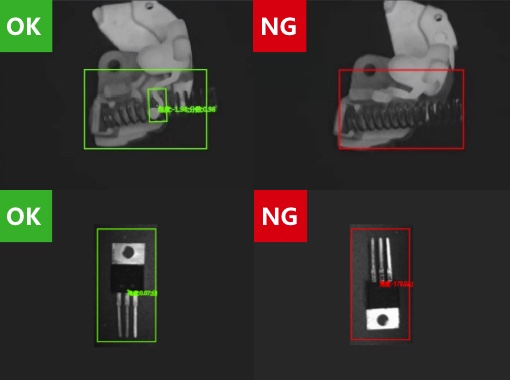

Defect Detection

Detect the scratch, damage, spot, color difference and other defects on the surface of electronic products.

In the process of manufacturing products in the electronic industry, defects can not be avoided, and the requirements of production enterprises for product quality are keeping raise. Therefore, defect detection is a very important application in the industry. Machine vision has the ability of high precision and high speed detection, which can realize the detection of various defects, including scratch, damage, spot, color difference, etc.

Let's talk about Machine Vision

Defect Detection

Detect the scratch, damage, spot, color difference and other defects on the surface of electronic products.

In the process of manufacturing products in the electronic industry, defects can not be avoided, and the requirements of production enterprises for product quality are keeping raise. Therefore, defect detection is a very important application in the industry. Machine vision has the ability of high precision and high speed detection, which can realize the detection of various defects, including scratch, damage, spot, color difference, etc.