OTC-DAIHEN

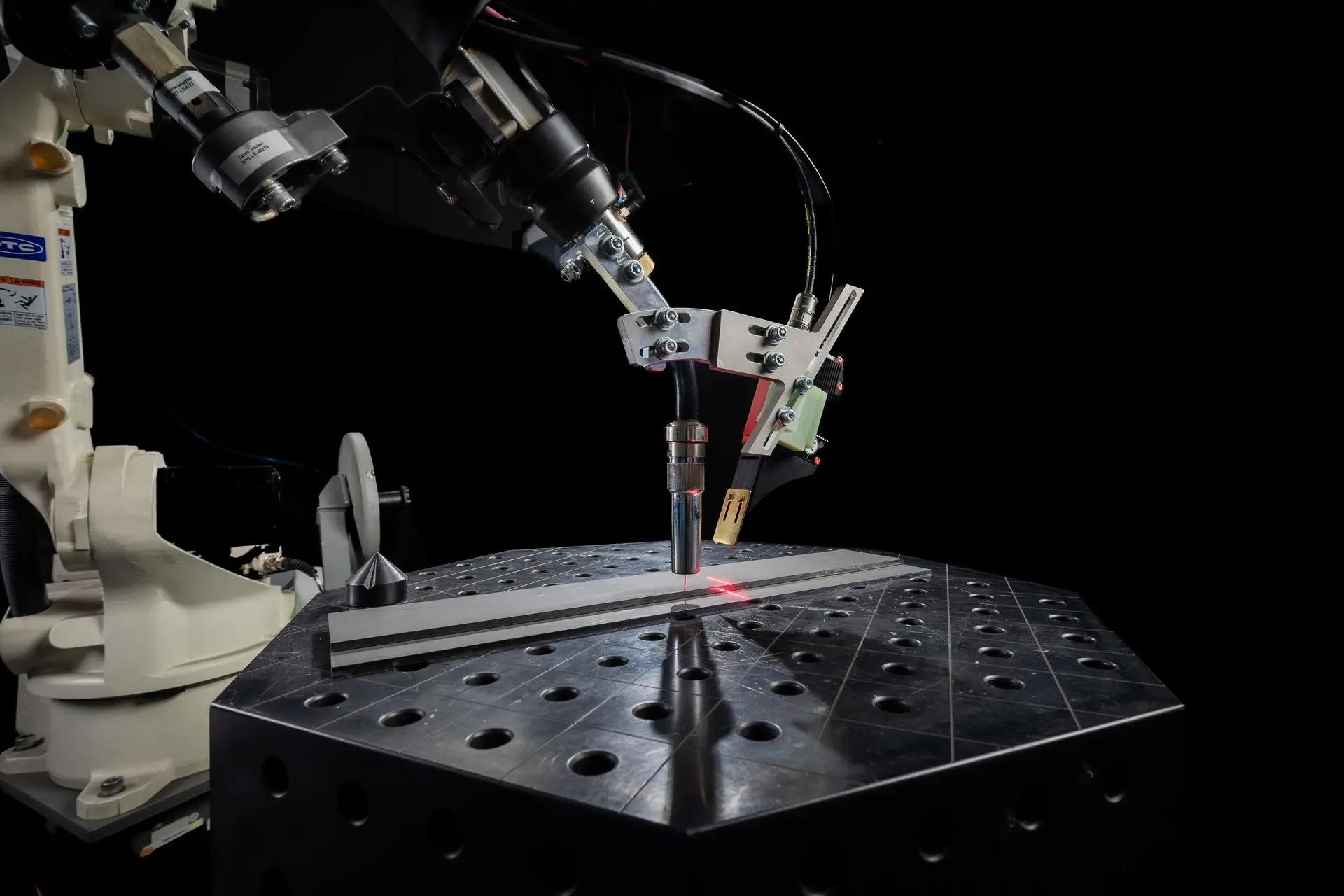

OTC-DAIHEN is renowned for its superior welding technology. Located in Japan with a large seat in Germany, they supply wide parts of the world with tools and technology that enable many industries to automate large parts of their welding tasks, most easily noticed in the automotive industry. If you need anything welded, automation with OTC-DAIHEN robots is the way to go. Let's get you familiar with OTC-DAIHEN.

Who is OTC-DAIHEN

In line with the OTC-DAIHEN motto "Joining Forces", OTC brings together expertise from a wide range of fields to implement state-of-the-art industrial solutions; combining robot technology, welding and cutting power sources, and accessories to create innovative solutions for the worldwide industry. With the competences to construct unique turnkey automation solutions, OTC-DAIHEN plays a huge role in the progression of welding automation in Europe and Asia.

FUN FACT

Did you know that the abbreviation "OTC" stands for Osaka Transformer Company, which was the original name of the company when founded in 1919? Since then, the company name has changed to DAIHEN Cooperation. The 'OTC' part of the name of the german office, OTC-DAIHEN, could then be said to be quite redundant.

History of OTC-DAIHEN

DAIHEN was founded in Osaka, Japan in the year 1919. Growing as a company, DAIHEN was listed on the Osaka Securities Exchange in 1953, and branching out to the USA in 1979, and Europe in 1982 with many more subsidiaries during the 00's and 10's. Originally, OTC specialized in production of pole-mounted transformers by adopting the Ford's mass production system. In the 1930s, they began producing electric welding machines. Since then, DAIHEN has been a leading industry giant in the production of welding equipment.

Benefits to OTC Welding Technology

Welding has become an increasingly difficult industry to find qualified workforce to. Bringing in the automation of welding tasks, and finding applications for welding robots for precise welding results, is beginning to seem like the best way forward. Standardizing your quality with welding robots, and using equipment with superior heat and tool precision creates better and consistent results for your production.

Six Benefits to Welding Automation

Welding automation has many benefits that quickly returns your ROI.

Cost Efficiency

Better consistent quality, increased output, and decrease in material waste results in better cost efficiency overall. Welding automation simply improves your production capabilities.

Weld Quality

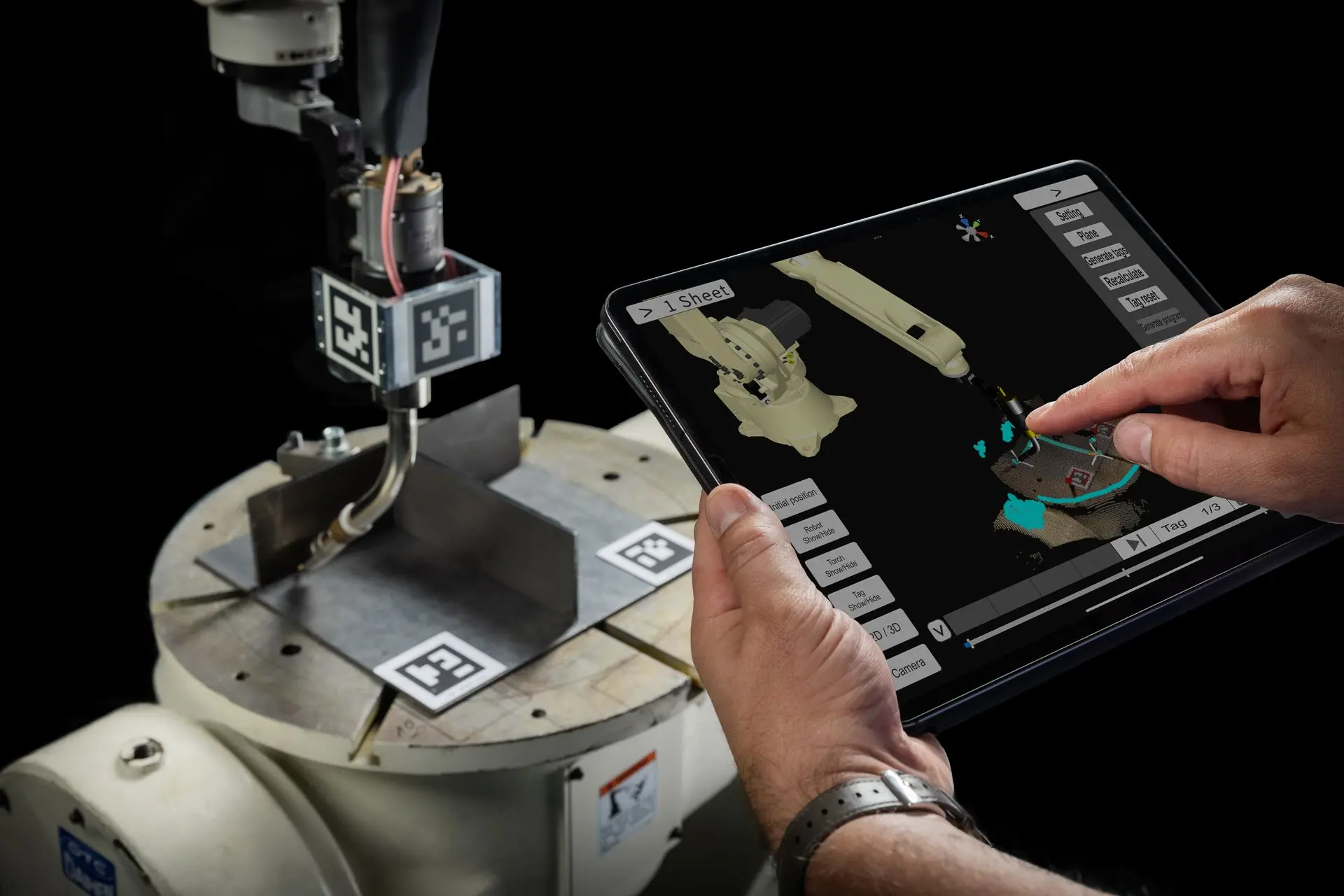

By using welding machines or robots, your expert welder can show the robot, or program, the best possible welding outcome.

Constant Quality

By using the best possible welding outcome indefinitely, you keep a constant good quality with welding robots and machines. Welding software has become so user-friendly that any welder can create the program needed to succeed.

Enhanced Safety

By having robots do the welding, you minimize the risk of injury on your welders.

Increase Output

Welding takes skill for quality work. By using robots yo ucan keep the best quality work over and over, in the same pace with no breaks.

Decrease in material waste and rework

Better consistent quality means few to zero mistakes. You won't need extra material as backup to ensure your quantity produced.

Let me introduce you to the OTC Welding System Solutions

EASY ARC

Entry Solution for welding automation

CUBE Solutions

Industrial solution for full scalable welding automation

Everything About Easy Arc

Everything About Cube Solutions