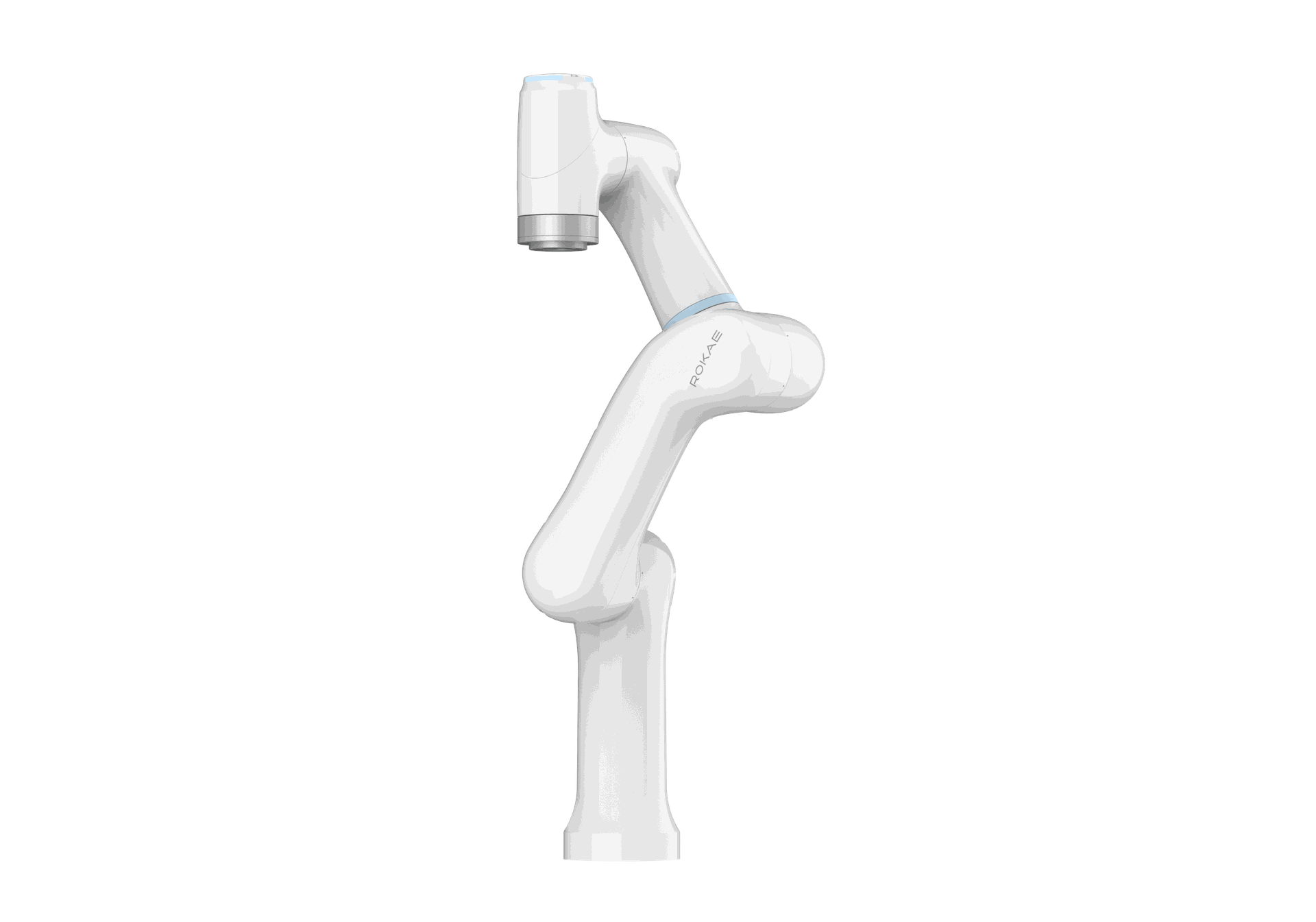

SR-C Series

Rokae Collaborative Robots

Apply the Rokae SR-C Series in a range of industries such as Healthcare, Commercial Services and the General Industry. Lightweight, great reach and easy to mount in any orientation. Robot automation has never been more intuitive, easy and safe.

Expanding upon the distinctive features and core advantages of the xMate SR flexible cobot, the xMate SR-C takes it a step further by relocating the controller to create an independent controller cabinet. This design caters to more confined base installation environments. Furthermore, the xMate SR-C undergoes a comprehensive upgrade, now supporting a 5 kg payload capacity.

ROKAE SR3-C

The Rokae SR3-C is built with an external controller. With over 21 adjustable safety features including collision detectoin, virtual walls, and collaboration mode, it's incredible safe and flexible for human-robot applicaitons. With ISO Clean class 5, and IP54, you can employ it in many production environments.

Max Payload (kg)

Max Reach (mm)

Number of Axis

Repeatability (mm)

IP Rating

Weight (kg)

Go to our webshop

Find prices, documents and more information on our products here!

ROKAE SR4-C

The Rokae SR4-C is built with an external controller. With over 21 adjustable safety features including collision detectoin, virtual walls, and collaboration mode, it's incredible safe and flexible for human-robot applicaitons. With ISO Clean class 5, and IP54, you can employ it in many production environments.

Max Payload (kg)

Max Reach (mm)

Number of Axis

Repeatability (mm)

IP Rating

Weight (kg)

Go to our webshop

Find prices, documents and more information on our products here!

ROKAE SR5-C

The Rokae SR5-C is built with an external controller. With over 21 adjustable safety features including collision detectoin, virtual walls, and collaboration mode, it's incredible safe and flexible for human-robot applicaitons. With ISO Clean class 5, and IP54, you can employ it in many production environments.

Max Payload (kg)

Max Reach (mm)

Number of Axis

Repeatability (mm)

IP Rating

Weight (kg)

Go to our webshop

Find prices, documents and more information on our products here!

ROKAE SR3

The Rokae SR3 is with a built-in controller for a tighter fit. With over 21 adjustable safety features including collision detectoin, virtual walls, and collaboration mode, it's incredible safe and flexible for human-robot applicaitons. With ISO Clean class 5, and IP54, you can employ it in many production environments.

Max Payload (kg)

Max Reach (mm)

Number of Axis

Repeatability (mm)

IP Rating

Weight (kg)

Go to our webshop

Find prices, documents and more information on our products here!

ROKAE SR4

The Rokae SR4 is with a built-in controller for a tighter fit. With over 21 adjustable safety features including collision detectoin, virtual walls, and collaboration mode, it's incredible safe and flexible for human-robot applicaitons. With ISO Clean class 5, and IP54, you can employ it in many production environments.

Max Payload (kg)

Max Reach (mm)

Number of Axis

Repeatability (mm)

IP Rating

Weight (kg)

Go to our webshop

Find prices, documents and more information on our products here!

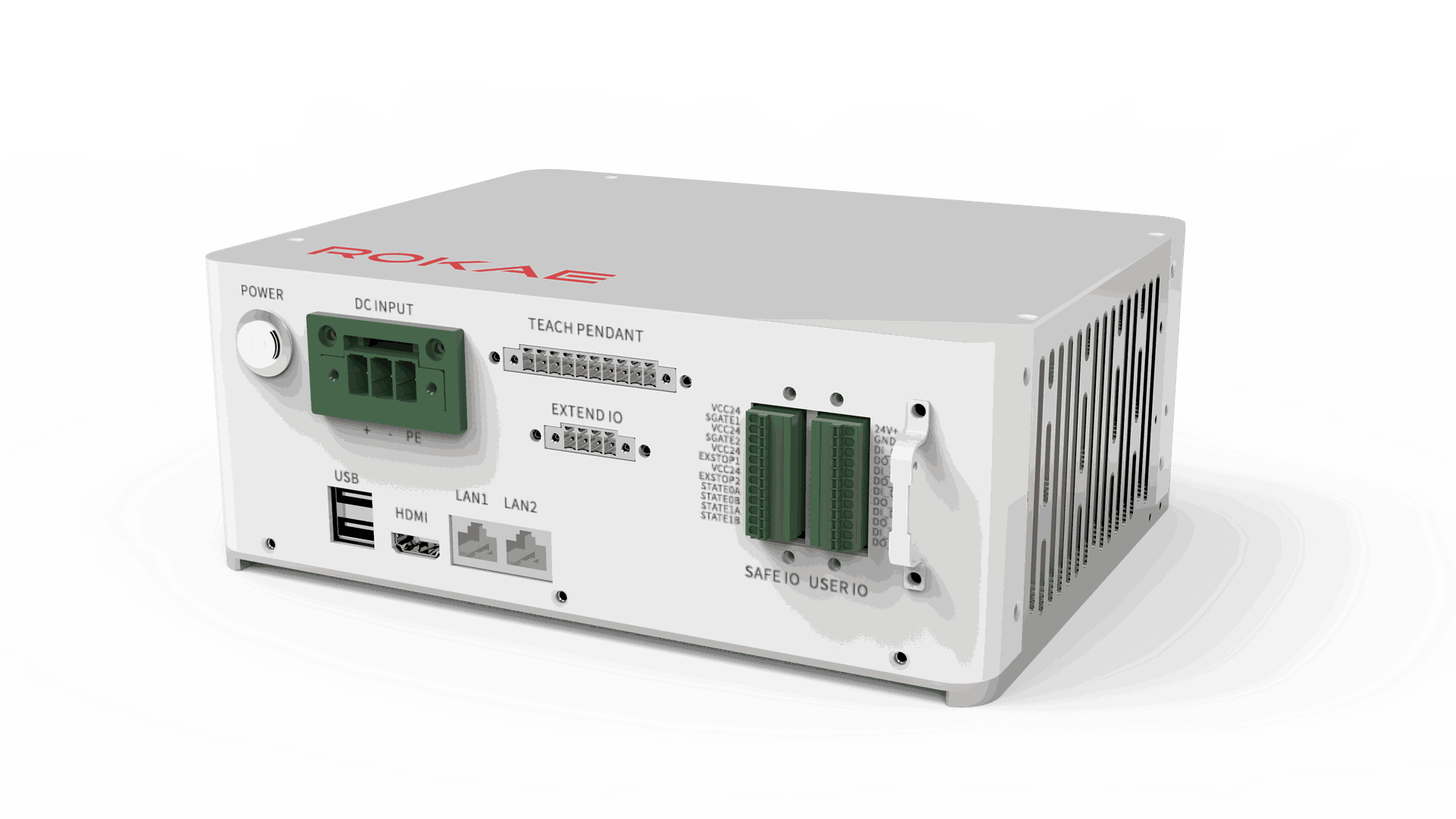

SR Series LightCab Controller

The Rokae SR Series LightCab controller is the applicable controller with the SR cobots. With a weight of 2.4 kg, it's easily implemented with the low-weight SR-C cobots. The Lightcab controller can be integrated with the SR3 and SR4 robot foot for a tighter fit.

Max Payload (kg)

Max Reach (mm)

Number of Axis

Repeatability (mm)

IP Rating

Weight (kg)

Go to our webshop

Find prices, documents and more information on our products here!

Stay Lightweight and flexibly with the SR-C

High-precision torque sensors in all joints enable ultra-sensitive force sensing, thus effectively avoiding accidental colisions and injuries, and ensuring safe operation.

The Innovative design brings superb lightweight flexibility as well as user-friendly human-machine interaction, shattering stereotypes about robots.

Industry-leading 80.000 hours of MTBF (Mean Time Between Failure) makes it an economical and solid partner.

Extremely easy to use and deploy, allowing quick installation and commissioning by beginners.