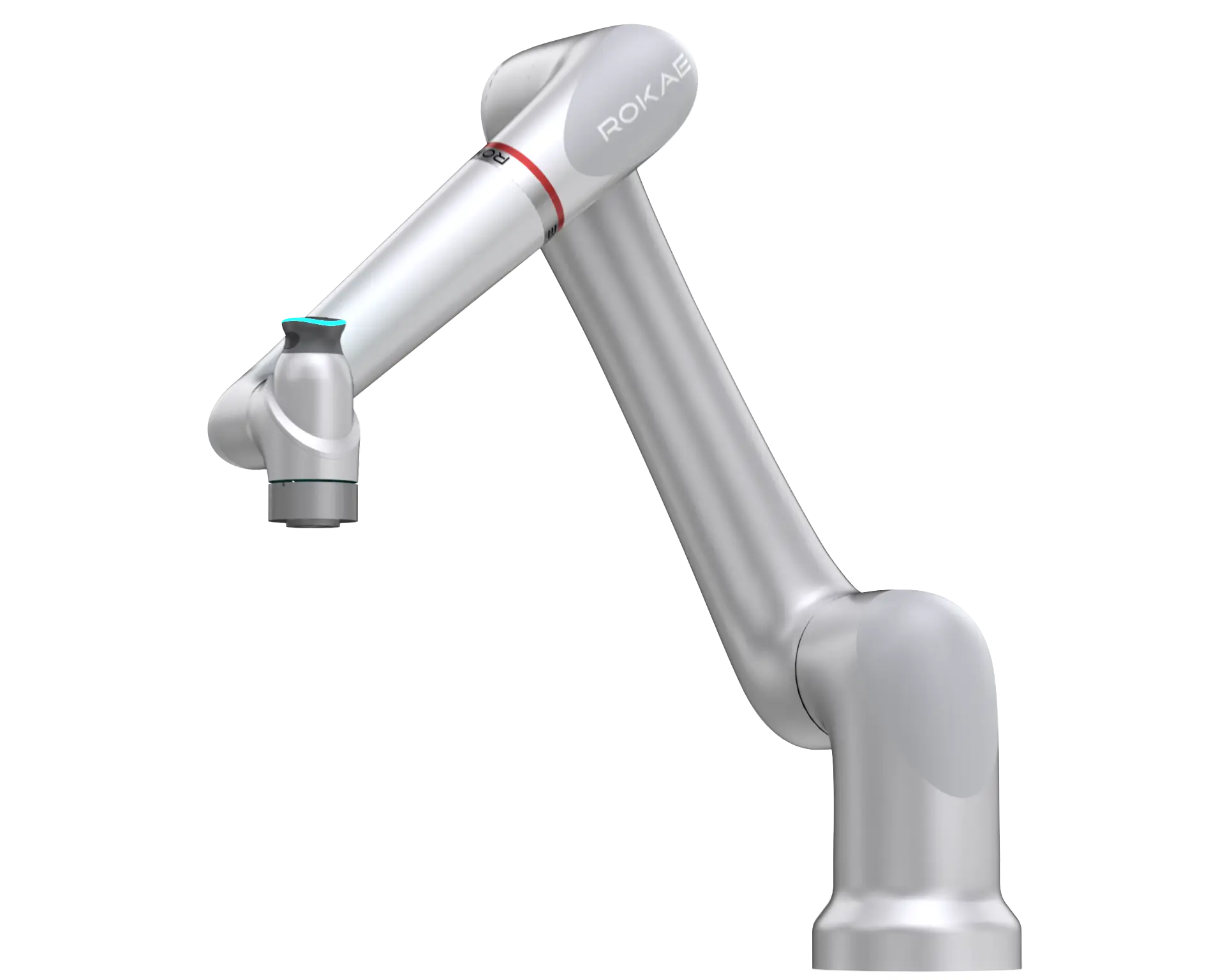

CR-C Serien | 6 Akser

Rokae Kollaborative Robotter

Tag et kig på de nye revolutionerende 6-akset samarbejdsrobotter fra Rokae CR-C serien. Controlleren i bunden af CR serien er flyttet ud af kroppen for at danne et uafhængigt kontrolskab med IP54 beskyttelsesniveau, hvilket reducerer installationsstørrelsen af basen og forbedrer beskyttelsesniveauet af kroppen til IP67, hvilket kan tilpasses mere krævende anvendelsesscenarier.

Det uafhængige kontrolskab tilbyder rigere IO-ressourcer og mere fleksibel udvidelsesmulighed. Dets indbyggede uafhængige sikkerhedscontroller, TÜV-certificeret, opfylder funktionel sikkerhed efter ISO 13849-1:2015 standarden, op til PL d / Cat. 3 niveau.

Den nyopgraderede xMate CR-C-serie af fleksible cobots udvider yderligere anvendelsesscenarier med egenskaberne sikrere, mere fleksible og nemmere at bruge.

Rokae CR-C Serien

Rokae cobot CR7-C

Rokae cobot CR7-C med en ekstern controller for øget ydeevne er fantastisk til materialehåndtering sammen med dine medarbejdere. Kraftmomentføler for øget følsomhed og trykpræcision på dine dele for optimal pleje, samarbejde og sikkerhed. Med en nyttelast på 7 kg og næsten 1000 mm rækkevidde er det en fremragende startcobot.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae cobot CR12-C

Rokae cobot CR12-C med en ekstern controller for øget ydeevne er fantastisk til materialehåndtering sammen med dine medarbejdere. Kraftmomentføler for øget følsomhed og trykpræcision på dine dele for optimal pleje, samarbejde og sikkerhed. Med en nyttelast på 12 kg og en rækkevidde på over 1400 mm passer den ind i mange industrielle samarbejdsmiljøer.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae cobot CR18-C

Rokae cobot CR18-C med en ekstern controller for øget ydeevne er fantastisk til materialehåndtering sammen med dine medarbejdere. Kraftmomentføler for øget følsomhed og trykpræcision på dine dele for optimal pleje, samarbejde og sikkerhed. Med en nyttelast på 18 kg og en rækkevidde på over 1000 mm er denne cobot ideel til applikationer på tæt hold.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae cobot CR20-C

Rokae cobot CR20-C med en ekstern controller for øget ydeevne er fantastisk til materialehåndtering sammen med dine medarbejdere. Kraftmomentføler for øget følsomhed og trykpræcision på dine dele for optimal pleje, samarbejde og sikkerhed. Med en nyttelast på 20 og næsten 1800 mm rækkevidde, overskrider denne cobot grænserne for den nuværende industrielle standard.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae CR Series

Rokae CR7

The Rokae CR7 cobot with an internal controller great for material handling together with your employees. Force torque sensor for increased sensitivity and pressure precision on your parts for optimal care, collaboration and safety. With a payload of 7 kg and 988 mm reach, this cobot works perfectly for many collaborative tasks.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae CR12

The Rokae CR12 cobot with an internal controller great for material handling together with your employees. Force torque sensor for increased sensitivity and pressure precision on your parts for optimal care, collaboration and safety. With a payload of 12 kg and 1434 mm reach, this cobot works perfectly for many collaborative tasks.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae CR18

The Rokae CR18 cobot with an internal controller great for material handling together with your employees. Force torque sensor for increased sensitivity and pressure precision on your parts for optimal care, collaboration and safety. With a payload of 18 kg and 1062 mm reach, this cobot works perfectly for many collaborative tasks.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Rokae CR20

The Rokae CR20 cobot with an internal controller great for material handling together with your employees. Force torque sensor for increased sensitivity and pressure precision on your parts for optimal care, collaboration and safety. With a payload of 20 kg and 1798 mm reach, this cobot works perfectly for many collaborative tasks.

Maks Løfteevne (kg)

Maks. rækkevidde (mm)

Antal akser

Præcision (mm)

IP Rating

Vægt (kg)

Gå til webshoppen

Find prices, documents and more information on our products here!

Force Torque Sensor til enhver præcis applikation

Den utroligt præcise kraftmoment-sensor i Rokae cobot-serien gør den til en strålende følgesvend på produktionslinjen. Anvendelser, der kræver en fin og venlig berøring, kan nemt håndteres af Rokae samarbejdsrobotter

Hvordan virker det?

Ved at omdanne en mekanisk inputkraft såsom belastning, vægt, spænding, kompression eller tryk til en anden fysisk variabel ind i et elektrisk outputsignal, der kan måles, konverteres og standardiseres, kan robotten 'føle' den kraft, den udøver på objektet. Når kraften påført kraftsensoren øges, ændres det elektriske signal proportionalt.

Vil du teste, om vores cobot kan håndtere dine følsomme produktionsbehov?

Styrk din produktion med Rokae

Den pålidelige partner for udstyrsproducenter og integratorer, der imødekommer omfattende branche-plugins og sekundær udvikling. Solidt økosystem, der fuldt ud styrker industriapplikationer. Kraftkontrolproceskit, palleproceskit og laser svejseproceskit. Vi gør det nemt for dig at integrere din løsning til dine behov med Rokae samarbejdsrobotter.